This chapter contains the following topics:

Use this function to enter purchase order receipts or vendor returns transactions that automatically update information in product purchasing, item inventory, and vendor performance files or tables.

Posting of transactions occurs "on line" during the entry process. However, history records are automatically created for each transaction and adjusting transaction procedures are available to correct previous entry errors.

There are some general rules about entering P.O. receipt and return transactions:

| • | You are allowed to enter Receipt or Return to Vendor transactions for a P.O. line item only if the P.O. is Open and the line item receiving status is still Open. |

| • | If a P.O. line item was previously Closed for receiving, you may use the "Purchase orders" entry program to change line item status to Open. If the entire P.O. was previously closed, you may use "Reopen closed orders" program on the menu for "Purchase orders", to reopen the P.O. and selective line items. |

| • | Before you are allowed to enter a Return To Vendor Transaction, an approved Rejected Material Authorization (RMA) must also be on file for the P.O. line item. When you enter the Return To Vendor transaction, you will be prompted to enter the related RMA Number. |

Select

Enter receipts & returnsfrom the Receipts & returns menu.

Enter the following fields:

1. Your initials

Entry Format: Up to 3 alphanumeric characters.

2. Transaction date

Entry Format: 6 numeric digits in MMDDYY format.

Default: The System Date is displayed as the default entry.

These fields will be posted to all subsequently entered transactions, until you exit the program.

If I/M Control Information indicates that you use Multiple Stock Locations, you also enter:

3. Default receiving location code

Entry Format: Up to 5 alphanumeric characters, or Blank = "Undefined".

Comment: This will be the default Location code entry when you enter the detail quantity distributions for Receipt or Return to Vendor transactions.

The receipt & return transaction screen now displays.

The data you enter are:

1. Trans type (Transaction type)

Entry Format: R = Receipt, or RV = Return To Vendor.

Comment: The Transaction Type stays constant for subsequent transactions, until you press ESC at Document Number to return to this field.

2. Document #

Entry Format: Up to 6 numeric digits, or press <F1> to automatically assign the next Document Number from Control Information.

Default: After entry for the first transaction, the value for the previous transaction displays as the default entry, which you may change after you complete all transactions for one shipment.

Comments: You may use your own externally assigned Receiving Document Numbers, or use Document Numbers automatically assigned by the program.

3. P.O. #

Entry Format: Up to 6 numeric digits.

Validation: Must match an open P.O.

If the number matches a Blanket P.O. Release, you are prompted to enter Release Number.

Rls # (Blanket Release Number)

Entry Format: Up to 2 numeric digits.

The number entered and the P.O. Number must match an open Blanket Release.

If the P.O. Number matches an open order, the Ship To Warehouse, Vendor Number, and Vendor Name are displayed. You may then find the P.O. line item to be received by entering Line Number, or Item Number and Warehouse, as follows:

4. Line #

Entry Format: Up to 3 numeric digits, or <F1> to display the next line item record for the P.O., or Blank to lookup by Item Number.

When using the Line Number entry method, you may press <F1> to get and display consecutive line items until the item you want appears. You may need to use <F1> to get split schedule records that are beyond the first delivery date for a split schedule Line Number.

Validation: Must match a line record for the P.O. Number. Line item data displayed includes Due Date, Item Number, Description, Open or Closed status, For Warehouse code, and Vendor Item Number if any.

Comments: If you selected the Item Number entry method, the cursor moves to:

Item #

Entry Format: Up to 15 alphanumeric characters, or Blank to return to Line Number.

For whse

Entry Format: Up to 2 alphanumeric characters, or Blank for "Main".

Validation: Item Number and Warehouse must match an open line record for the P.O. Number. Line item data displayed includes Due Date, Line Number, Description, Open or Closed status, For Warehouse code, and Vendor Item Number, if any.

If you entered a valid Line Number, the program asks

"Right line record ?".

Answer Y to proceed, or press <F1> to display the next line record for the P.O., or answer N. If you answer N, the cursor returns to the Line Number position.

If you entered a valid Item Number and Warehouse, the program displays the first matching Open line record (the earliest open Due Date) and asks

"Right due date ?".

Answer Y to proceed, or press <F1> to display the next open record, if any, matching your entries, or answer N. If you answer N, the cursor returns to Item Number.

When you use the Line Number entry method, the program displays both Open and Closed line records, but will only allow you to proceed if you select an Open record. When you use the Item Number entry method, the program only retrieves Open records matching your entries.

After the first completed transaction, the program will default to the line item entry method (Line Number or Item Number) that you used for the previous transaction.

If one receipt quantity for an item covers more than one Due Date (more than one P.O line schedule record for that item), you should split the received quantity into more than one transaction. Splitting the receipt will properly apply quantities to the proper P.O. line schedule records for delivery performance measurement.

If the P.O. line record you select already has a completed transaction in history for the same Document Number and same Date, the program warns you about this condition. You are then given the option to proceed adding another transaction, possibly a correcting transaction, or to cancel the transaction.

When you find the right line record, you enter:

5. Rcv at whse

(Received at warehouse, for Receipts)

Rtn from whse

(Returned from warehouse, for Returns)

Entry Format: Up to 2 alphanumeric characters, or space for "Main".

Default: The "For Warehouse" code for the P.O. item, if not "Main", is displayed as the default entry.

Validation: If not "Main", must match a record in I/M Warehouses.

Comments: For inventory items, this is the Warehouse at which the Quantity On Hand will be updated by the transaction. If this is not the "For Warehouse", you will later have to use Inventory Management to transfer received quantities to the "For Warehouse" location.

This warehouse could be Receiving Inspection.

The Quantity On Order will always be updated for the "For Warehouse".

For a Return transaction, you must next enter:

RMA #

(Rejected Material Authorization Number)

Entry Format: Up to 15 alphanumeric characters.

Validation: Must match an approved RMA record for this P.O. line item, and the answer to "OK to return ?" must be Y in that RMA record. The program informs you of any exceptions.

6. Quantity received or returned

Entry Format: Up to 8 numeric digits plus 3 decimals, with an optional minus sign.

Validation: If the total quantity Received to date, including this transaction, exceeds the quantity ordered, the program warns you of this condition and displays the quantities.

If a Return quantity exceeds the quantity Received to date, such that the new Received quantity would be negative, these invalid results are displayed with an Invalid Quantity message, and you are prompted to enter another quantity.

Comments: The optional minus sign should only be used to correct previous transaction errors. You do not need to enter a minus sign for a Return quantity, since Return quantities of inventory items are subtracted from On Hand.

If the answer is N to "Display/change unit costs when receiving orders ?" in P/P Control Information , the following entry is bypassed and the Unit Cost in the P.O. line record is used for the transaction. Otherwise, you may change:

7. Est unit cost

Entry Format: Enter spaces to accept the default entry displayed from the P.O. line record, or

Press <F1> to enter another value, up to 6 numeric digits plus 4 decimals.

Comments: The program displays a Y or N answer to Outside cost ? to indicate if the P.O. line item is for Outside Processing of your material.

The program displays Before and After values of warehouse On Hand for inventory items, the P.O. line Quantity Ordered, and the Before and After values of Quantity Received.

If the total Quantity Received exceeds the allowed over-shipment percent specified in Control Information, the program informs you about this exception and gives you the option to cancel or post the transaction.

If the Transaction Date is earlier than the line item Due Date by more than the number of allowed early shipment days specified in Control Information, the program informs you about this exception and gives you the option to cancel or post the transaction.

If the total Quantity Received equals or exceeds the line item Quantity Ordered, the program automatically closes the P.O. line item for receiving. If total Quantity Received is less than total Quantity Ordered, the program asks "OK to close ?". Answer N to keep the line record open for more receipts, or Y to close it.

If you use Multiple Stock Locations, or Lot or Serial Number Control is specified for the item, you must next complete detail quantity distribution entries as explained in the next section of this chapter.

If the Vendor Number for the P.O. receipt matches a record in Vendor Warehouses and a Bill Of Material is on file for the received item, the program asks " OK to explode vendor material issues ?". If you answer Y, the program explodes the transaction quantity into component item issues at the Vendor Warehouse. This is a single level explosion. If P.O. line "Outside cost ?" is "Y", indicating outside vendor processing, total value of the component materials used is also transferred from the Vendor Warehouse to the Receiving Warehouse as a pseudo Item Number "OUTSRC*MATL*COST" in Inventory Transaction History.

If you use Multiple Stock Locations, or Lot or Serial Number Control is specified for the item issued at the vendor Warehouse, you must then complete detail quantity distribution entries as explained in the next section of this chapter.

For Receipt transactions, the program will ask "Immediate issue of this receipt ?". If you answer Y, you must enter:

6. Order type

Entry Format: C = Customer, S = Shop, or M = Misc. issue.

Comment: If you use PBS Manufacturing Customer Order Processing, you are not allowed to issue to a Customer Order with this program.

If Order Type = M, you also enter:

Acct #

Entry Format: Up to the number of digits for Main Account Number, and Sub-account Number, that is specified for Account Number sizes in your Company information.

Validation: Must match a record in Valid G/L Accounts, in which case its description is displayed and you are asked to confirm the entry.

Comments: This is the account to which the Miscellaneous Issue (or Return to Stock) will be charged in the I/M Distribution to General Ledger. It may be a non-inventory expense account.

7. Order #

Entry Format: Up to 6 alphanumeric characters.

For Order Type = "Misc", this field is automatically entered as "Misc".

For Order Type = Shop, you may optionally enter spaces for "Misc".

Validation: For Order Type = Shop, if your entry is not spaces, it must match a record in Shop Order Material Requirements created in Inventory Management. You are then prompted to enter:

Rls # Up to 2 numeric digits, or space.

Validation: The combination of Order Number, Release Number, Parent Item Number, and the Component Item Number to be issued must match a record in Shop Order Material Requirements.

8. Qty issued

Entry Format: Enter spaces to accept the default value of the Receipt quantity displayed, or, press <F1> to enter up to 8 numeric digits plus 3 decimals.

If you use Multiple Stock Locations, or Lot or Serial Number Control is specified for the item, you must next complete detail quantity distribution entries as explained in the next section of this chapter.

If you wish to escape from the Immediate Issue entry routine without completing the transaction, you may press ESC at the Order Type position.

For Receipt transactions, if you maintain the Vendor Shipments In-Transit and the P.O. line item matches a Shipment In-Transit record, the program displays the first matching record and asks "Post receipt to this in-transit record ?". Answer Y to post, or answer N to display any more matching In-Transit records. When no more matching records are found the program asks "No more matching in-transit records - redisplay matching records ?". Answer Y or N.

After a Receipt or Return transaction is completed, the program asks "Another receipt (or return) for this P.O. ?". If you answer Y, the cursor returns to the Line Number entry position. Otherwise, you are returned to Document Number where you may continue entering transactions for the same Document Number, enter another Document Number, or press ESC.

When you press ESC at Document Number, the cursor moves to Transaction Type where you may change the Transaction Type, or press ESC to exit the program.

Receipt and Return transactions for inventory items automatically update Quantity On Hand and Quantity On Order balances and create Inventory Transaction History records. P.O. Receipt & Return history records are created for all P.O. items. Receipt transactions for all P.O. items also update delivery performance statistics in Vendor Performance Summary and in any matching Item Sources.

You cannot retrieve a previously entered Receipt or Return transaction to change it or delete it, since these transactions are posted when you press ENTER at "Field number to change ?". However, you can correct errors in a previously entered transaction by typing in another transaction for the same Transaction Date, Transaction Type, Document Number, P.O. Number, and Line Number. Then enter a plus or minus quantity in the correcting transaction to adjust or negate the original transaction.

Multiple Stock Location or Lot/Serial Number Quantity Distribution

If you use Multiple Stock Locations, or if Lot or Serial Number control applies to the item inventory transaction, you are prompted to enter detail transaction quantity distributions on a subsequent screen. The detail distribution entry screen displays the Item Number and Description, Transaction Type, total Transaction Quantity, and the Quantity (remaining) To Distribute. Existing on hand detail is also displayed on the bottom section of this entry screen. You must enter detail quantity distributions (to locations and/or Lot or Serial Numbers) until Quantity To Distribute is zero. Then press ESC to exit this screen.

The detail quantity distribution data you enter are:

1. Detail qty

Entry Format: Up to 8 numeric digits plus 3 decimals, with an optional minus sign.

Default: For a Serial # control item, 1 is the default. Otherwise, remaining Quantity To Distribute is displayed as the default quantity. Press <F1> if you wish to change the default quantity.

Comments: Normally, you should enter distribution quantity with the same sign as the total Transaction Quantity that is displayed. Issue, Stock Scrap, or Sale quantity distributions will automatically subtract from on hand detail balances when entered as positive distributions. You may use an opposite sign, however, to reverse a previously entered quantity distribution.

Detail seq #

Entry Format: Up to 2 numeric digits, matching the Sequence Number of an On Hand Detail line displayed below, or enter spaces to bypass. If there are more On Hand Detail records than can fit on the screen, press <F1> to display more detail.

Comment: Typing a number here automatically assigns the Location and/or Lot or Serial # of an existing On Hand Detail record to the quantity distribution you are entering.

If Lot or Serial Number control applies to the item transaction, you enter:

2. Lot # (or Serial #)

Entry Format: Up to 15 alphanumeric characters, or Blank for "Undefined".

For receipts or returns of a Lot # Control item, the first part of the Lot Number automatically becomes the Order Number, followed by a Release Number if there is an Order Release Number, and a "*" character. You may append the automatically assigned portion of the Lot Number.

If Multiple Stock Locations are specified in I/M Control Information, you enter:

3. Location

Entry Format: Up to 5 alphanumeric characters, or Blank for "Undefined".

The following field is optional, but may be entered by using "Field number to change ?":

4. Reference

Entry Format: Up to 25 alphanumeric characters.

Comment: You may wish to enter a Vendor Name or Customer Name, depending on the transaction type.

The program deducts the Detail Quantity from the Quantity to Distribute and updates the On Hand Detail records. The new balances are then redisplayed, and the cursor returns to the Detail Quantity position. When Quantity To Distribute has been reduced to zero, you may press ESC at the top entry position to exit the screen; otherwise, continue entering additional quantity distributions until Quantity To Distribute is zero.

Use this program to enter information about purchased material quality discrepancies discovered at receiving inspection or thereafter, to approve the Rejected Material Authorization, and to track vendor corrective action status.

The open or closed P.O. line item related to the received material to be rejected must be on file when you initially type in the Rejected Material Authorization (RMA). This should be done when discrepancy reports or forms are submitted by quality control or manufacturing personnel responsible for inspection.

RMA approval entry can optionally be deferred until further review of the reported discrepancy. When approval fields are entered, the program asks if it is OK to return the material to the vendor. Upon approval entry, statistics about rejects are updated in the Vendor Performance Summary and in any matching Item Source File record.

Before you are allowed to enter a Return To Vendor Transaction with the "Receipts & returns" entry program, an approved Rejected Material Authorization must be on file for the P.O. line item, and that RMA record must indicate it is OK to return the material.

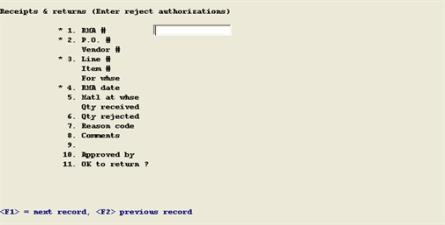

Select

Enter reject authorizationsfrom the Receipts & returns menu.

Enter the following fields:

1. RMA #

Entry Format: Up to 15 alphanumeric characters.

Comments: This is your internal Rejected Material Authorization (or Discrepancy Report) Number, not a vendor's Return Material Authorization Number which can later be entered to the Comments fields in this record.

2. P.O. #

Entry Format: Up to 6 numeric digits, or <F1> to display the next RMA record for the RMA Number.

Rls #

(Blanket Release Number, if any)

Entry Format: Up to 2 numeric digits, or Blank.

Validation: The combination of P.O. Number and Release Number, if any, must match an open or closed P.O. line item.

3. Line #

Entry Format: Up to 3 numeric digits, or press <F1> to display the next line item record for the P.O.

You may press <F1> to get and display consecutive line items until the item you want appears. You may need to use <F1> to get split schedule records that are beyond the first delivery date for a split schedule Line Number.

Validation: Must match a line record for the P.O. Number, and the line item for a new RMA record must contain a non-zero Quantity Received. Line data displayed includes Due Date, Item Number, Description, For Warehouse code, Quantity Received, Purchase Unit of Measure, and Vendor Item Number if any.

4. RMA date

Entry Format: 6 numeric digits in MMDDYY format, the System Date is the default displayed.

5. Matl at whse

(Material at warehouse code)

Entry Format: Up to 2 alphanumeric characters, or space for "Main".

Default: The "For Warehouse" code for the P.O. item, if not "Main", is displayed as the default entry.

Validation: If not "Main", must match a record in I/M Warehouses.

Comments: This is the Warehouse at which the material is currently located.

6. Quantity rejected

Entry Format: Up to 8 numeric digits plus 3 decimals.

Validation: This quantity cannot exceed the P.O. line item Quantity Received to date.

7. Reason code

Entry Format: Up to 2 alphanumeric characters.

Validation: Must match a code in Reject Reason Codes, in which case the description displays.

8.-9. Comments

Entry Format: Up to 2 lines of 30 alphanumeric characters each, or spaces.

These fields may be use to further describe the reason, to record the vendor's RMA Number, etc.

10. Approved by

Entry Format: Up to 3 alphanumeric characters, for person's initials, or spaces for "Not approved".

If Approved By is not spaces, you are prompted to type:

Approved date

Entry Format: 6 numeric digits in MMDDYY format, or enter spaces to accept the default date displayed.

11. OK to return ?

Entry Format: Y or N.

Comment: To allow a Return To Vendor transaction in the Enter Receipts & Returns program, this answer must be Y. However, some approved rejects may not be returned to the vendor.

Returned date

Displays after a Return To Vendor transaction with this RMA Number reference is processed with Enter Receipts & Returns.

12. Corrective action request date

Entry Format: 6 numeric digits in MMDDYY format, or spaces for None.

Designates date you requested corrective action report from vendor.

13. Vendor action plan reply date

Entry Format: 6 numeric digits in MMDDYY format, or spaces for None.

Designates date you received corrective action report from vendor.